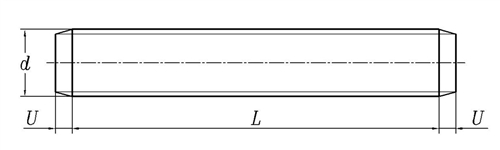

ANSI ASME B18.31.2 全螺纹螺柱 牙棒

工艺:

详细信息

ANSI ASME B18.31.2 全螺纹螺柱 牙棒 材质、等级:8.8级、10.9级、12.9级 、A2-70、A4-70 、A4-80等

表面处理:镀普通蓝白锌、普通彩锌、热镀锌、环保彩锌、环保蓝白锌、环保达克罗等

盐雾时间:可做72H、96H、120H、300H、360H、720H等高盐雾处理

电话咨询:400-086-0001 025-86183701-8026

徐小姐

邮件咨询:dm8026@18luosi.com

QQ咨询:2850588428

| Nominal Diameter | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 | 1-1/8 | 1-1/4 | 1-3/8 | 1-1/2 | 1-5/8 | 1-3/4 | 1-7/8 | 2 | 2-1/4 | 2-1/2 | 2-3/4 | 3 | 3-1/4 | 3-1/2 | 3-3/4 | 4 | ||

| d | 0.25 | 0.3125 | 0.375 | 0.4375 | 0.5 | 0.5625 | 0.625 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.375 | 1.5 | 1.625 | 1.75 | 1.875 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | ||

| PP | UNC | 20 | 18 | 16 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 7 | 6 | 6 | - | 5 | - | 4 1/2 | 4 1/2 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| UNF | 28 | 24 | 24 | 20 | 20 | 18 | 18 | 16 | 14 | 12 | 12 | 12 | 12 | 12 | - | - | - | - | - | - | - | - | - | - | - | - | ||

| 8UN | - | - | - | - | - | - | - | - | - | - | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||

| U | UNC / min | 0.05 | 0.056 | 0.063 | 0.072 | 0.077 | 0.084 | 0.091 | 0.1 | 0.111 | 0.125 | 0.143 | 0.143 | 0.167 | 0.167 | - | 0.2 | - | 0.222 | 0.222 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | |

| UNC / max | 0.1 | 0.111 | 0.125 | 0.143 | 0.154 | 0.167 | 0.182 | 0.2 | 0.222 | 0.25 | 0.286 | 0.286 | 0.333 | 0.333 | - | 0.4 | - | 0.444 | 0.444 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | ||

| UNF / min | 0.036 | 0.042 | 0.042 | 0.05 | 0.05 | 0.056 | 0.056 | 0.063 | 0.072 | 0.084 | 0.084 | 0.084 | 0.084 | 0.084 | - | - | - | - | - | - | - | - | - | - | - | - | ||

| UNF / max | 0.071 | 0.083 | 0.083 | 0.1 | 0.1 | 0.111 | 0.111 | 0.125 | 0.143 | 0.167 | 0.167 | 0.167 | 0.167 | 0.167 | - | - | - | - | - | - | - | - | - | - | - | - | ||

| 8UN / min | - | - | - | - | - | - | - | - | - | - | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | ||

| 8UN / max | - | - | - | - | - | - | - | - | - | - | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | ||

| ①,Stud ends shall be chamfered from the major diameter to a diameter equal to or less than the thread root diameter. The length of the chamfered end to the first full formed thread at major diameter, as determined by the distance the chamfered end enters into a cylindrical NOT GO major diameter ring gage, shall be one to two thread pitches on each end. The ends of the stud shall be reasonably square with the axis of the stud, but the slight rim or cup resulting from manufacturing shall be permissible. The ends shall be suitable for marking. | ||||||||||||||||||||||||||||